During the underwear manufacturing process, how to ensure that the wear resistance of

Underwear Poly Fabrics meets industry standards, so that the underwear remains intact after prolonged wear and washing?

During the underwear manufacturing process, ensuring that the wear resistance of Underwear Poly Fabrics meets industry standards and remains intact for a long time is a systematic project involving material selection, process control, quality testing, and consumer guidance. Here are some key steps and strategies:

1. Choose high-quality Poly Fabrics

Source control: Cooperate with reliable suppliers to ensure that Poly Fabrics’ raw materials are of high quality and that fiber strength, wear resistance, elasticity and other indicators meet industry standards.

Fiber ratio: According to the purpose and wearing needs of underwear, select the appropriate fiber ratio to optimize the wear resistance of the fabric.

2. Optimize production process

Weaving process: Advanced weaving technology is used to ensure a tight and uniform fabric structure and reduce the risk of wear and tear caused by weaving defects.

Sewing technology: Use appropriate sewing thread and sewing technology to ensure that the underwear does not cause excessive friction and wear during the sewing process.

3. Strict quality inspection

Wear resistance test: The produced Underwear Poly Fabrics are tested for wear resistance to ensure that the fabrics meet or exceed industry standards.

Finished product inspection: Conduct a comprehensive inspection of the finished underwear to ensure that there are no quality problems such as wear and pilling.

4. Provide correct washing and maintenance suggestions

Washing guidance: Provide correct washing methods in product labels or promotional materials to guide consumers to use mild detergents and appropriate washing methods to avoid unnecessary wear and tear on underwear during the washing process.

Maintenance recommendations: Consumers are advised to avoid contacting underwear with rough surfaces or sharp objects to reduce the possibility of wear and tear.

5. Continuous improvement and innovation

Research and develop new materials: Cooperate with scientific research institutions or universities to develop new Poly Fabrics materials with higher wear resistance.

Process upgrade: Continuously optimize the production process, introduce advanced production equipment and technology, and improve the wear resistance and overall quality of underwear.

Ensuring that the wear resistance of Underwear Poly Fabrics meets industry standards and remains intact for a long time requires manufacturers to make great efforts in material selection, process control, quality testing and consumer guidance. Through continuous optimization and innovation, underwear products with better wear resistance and durability can be produced to meet the needs of consumers.

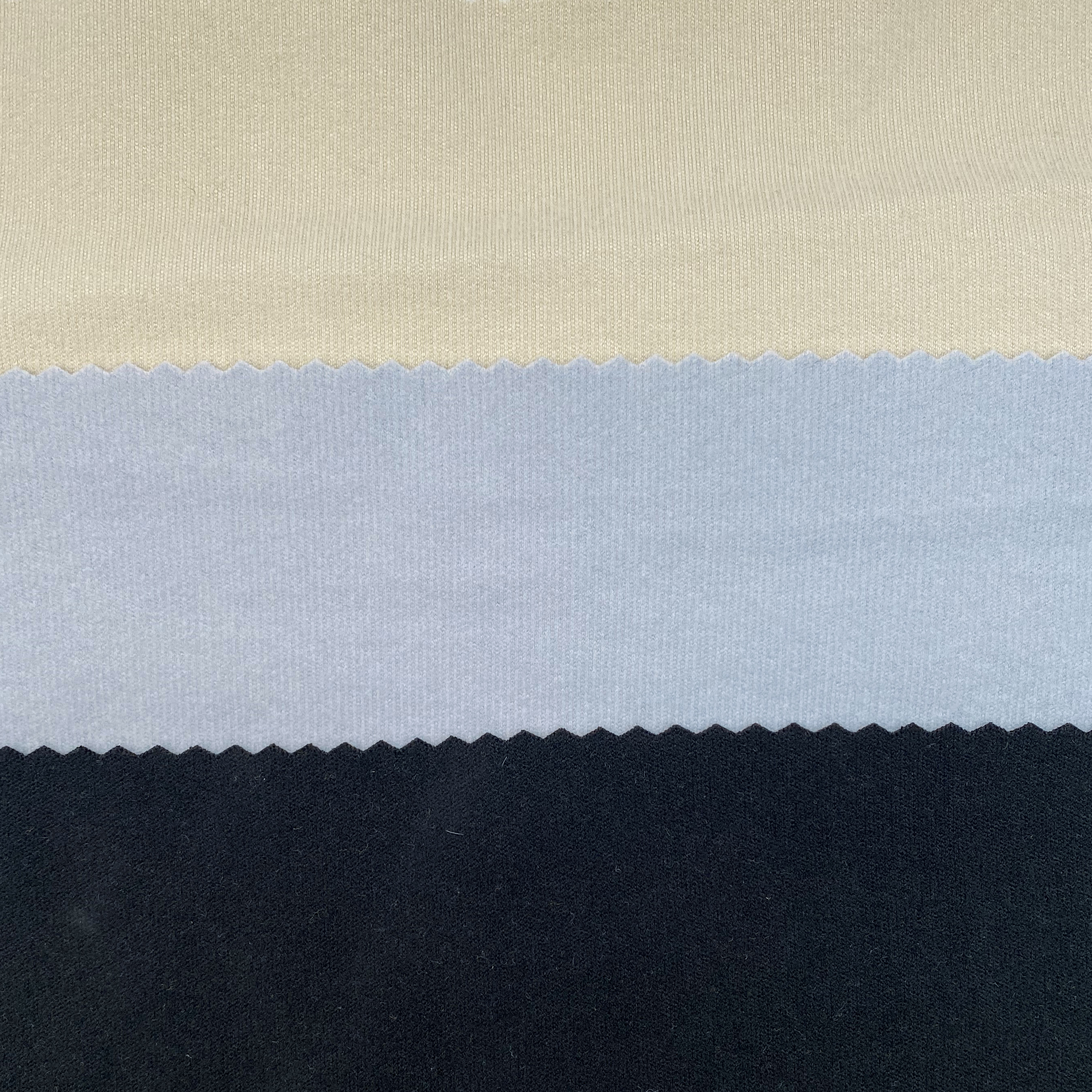

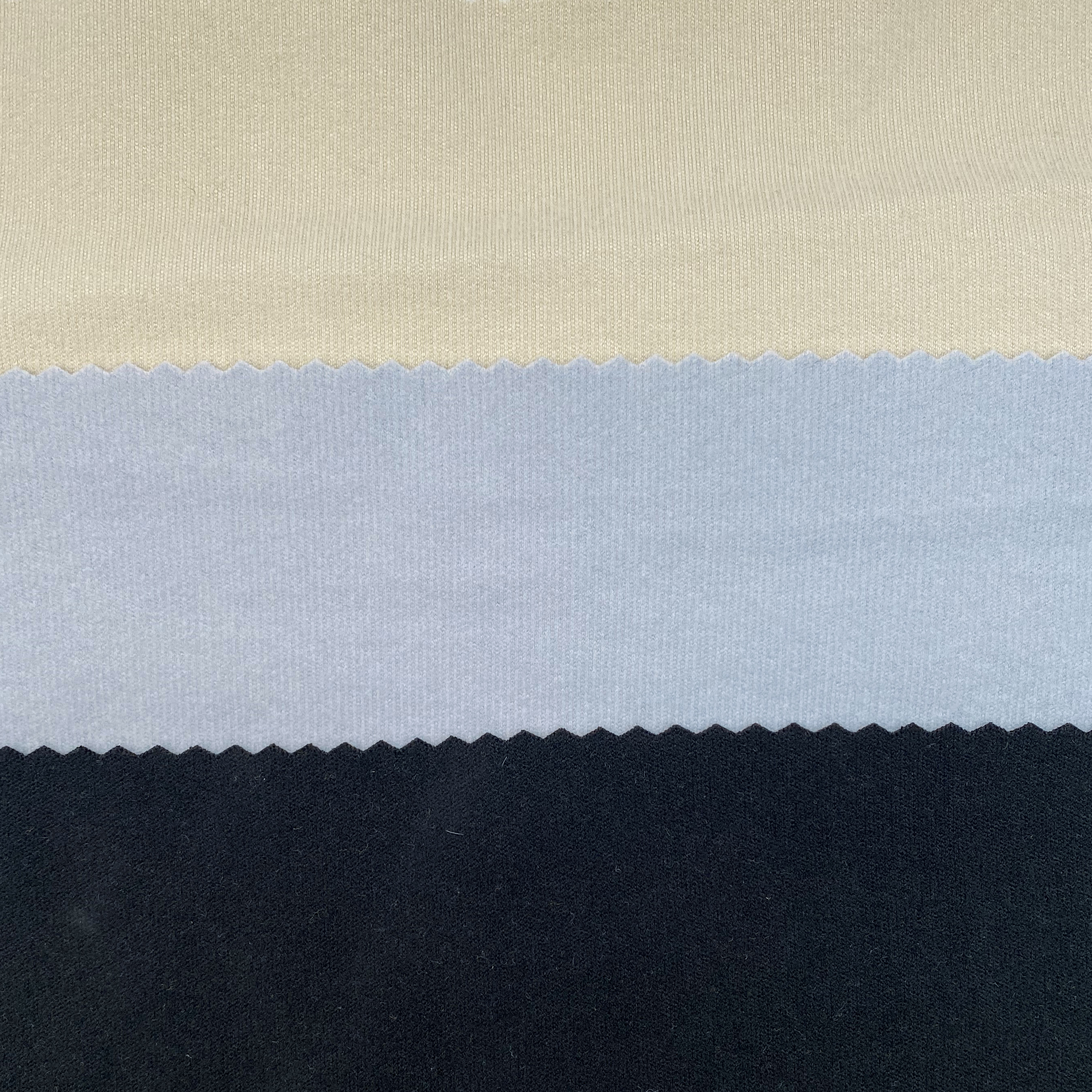

THERMAL UNDERWEAR FABRIC

THERMAL UNDERWEAR FABRIC