How is poly undies cloth engineered for chlorine resistance, and why is this selection crucial for purchasers, specifically those who have interaction in sports inclusive of swimming or water sports activities?

Polyester Underwear Fabric Engineering for Chlorine Resistance:

Polyester undies cloth is engineered for chlorine resistance via a aggregate of cloth choice, production procedures, and every so often additional treatments. Chlorine resistance is a crucial feature for consumers, specifically those who interact in sports like swimming or water sports, where exposure to chlorinated water is common.

Material Selection:

The preference of polyester as the number one material for underwear cloth lays the foundation for chlorine resistance. Polyester is inherently much less at risk of the corrosive consequences of chlorine as compared to a few natural fibers. Its synthetic nature and molecular structure offer a level of resilience against the chemical degradation that could arise whilst uncovered to chlorinated water.

Fabric Treatments:

Manufacturers frequently rent particular treatments at some point of the fabric manufacturing method to beautify chlorine resistance. These remedies can also include the software of protecting coatings or finishes that create a barrier, stopping chlorine molecules from penetrating the fabric and inflicting damage. This extra layer of protection helps hold the cloth's integrity, color, and general performance through the years.

Testing and Quality Control:

In the production of poly underwear cloth, best control measures encompass rigorous checking out for chlorine resistance. Fabric samples may go through simulated publicity to chlorinated water, permitting manufacturers to assess how nicely the material withstands repeated touch with chlorine. This trying out guarantees that the very last product meets the desired standards for durability and performance in chlorinated environments.

Significance for Consumers:

Extended Lifespan:

Chlorine resistance in poly underwear cloth interprets to an prolonged lifespan for the undergarments. Regular publicity to chlorinated water can accelerate the deterioration of less-resistant materials, main to shade fading, loss of elasticity, and standard put on and tear. Polyester's potential to withstand chlorine facilitates keep the structural integrity of the underclothes, making sure it stays long lasting and retains its unique first-rate over an prolonged duration.

Color Retention:

One excellent advantage of chlorine resistance in poly undies cloth is the preservation of coloration. Chlorine publicity can motive shades to fade in a few fabric, leading to a dull and worn-out appearance. Polyester's resistance to chlorine allows preserve the colors colourful and true, contributing to a visually appealing and well-maintained look.

Suitability for Water Activities:

Consumers who interact in water-primarily based sports, such as swimming or water sports, price chlorine-resistant underwear for its suitability in chlorinated swimming pools. Whether it is a lively swim session or a calming dip, chlorine-resistant poly underwear remains resilient, providing consolation and performance even after extended publicity to chlorinated water.

Versatility:

Chlorine resistance adds versatility to poly undies, allowing it to transition seamlessly between regular wear and activities involving water. Consumers can expectantly wear their polyester undies in diverse environments, understanding that it is able to face up to the challenges posed by means of chlorinated pools with out compromising on comfort or durability.

In conclusion, the engineering of

poly underwear fabric for chlorine resistance is a important factor of its manufacturing, making sure that the material can face up to exposure to chlorinated water. This characteristic enhances the lifespan of the underclothes, preserves color, and makes it a practical desire for consumers who participate in water-associated activities. As clients more and more are looking for flexible and sturdy undergarments, the emphasis on chlorine resistance stays a key attention for manufacturers within the fabric industry.

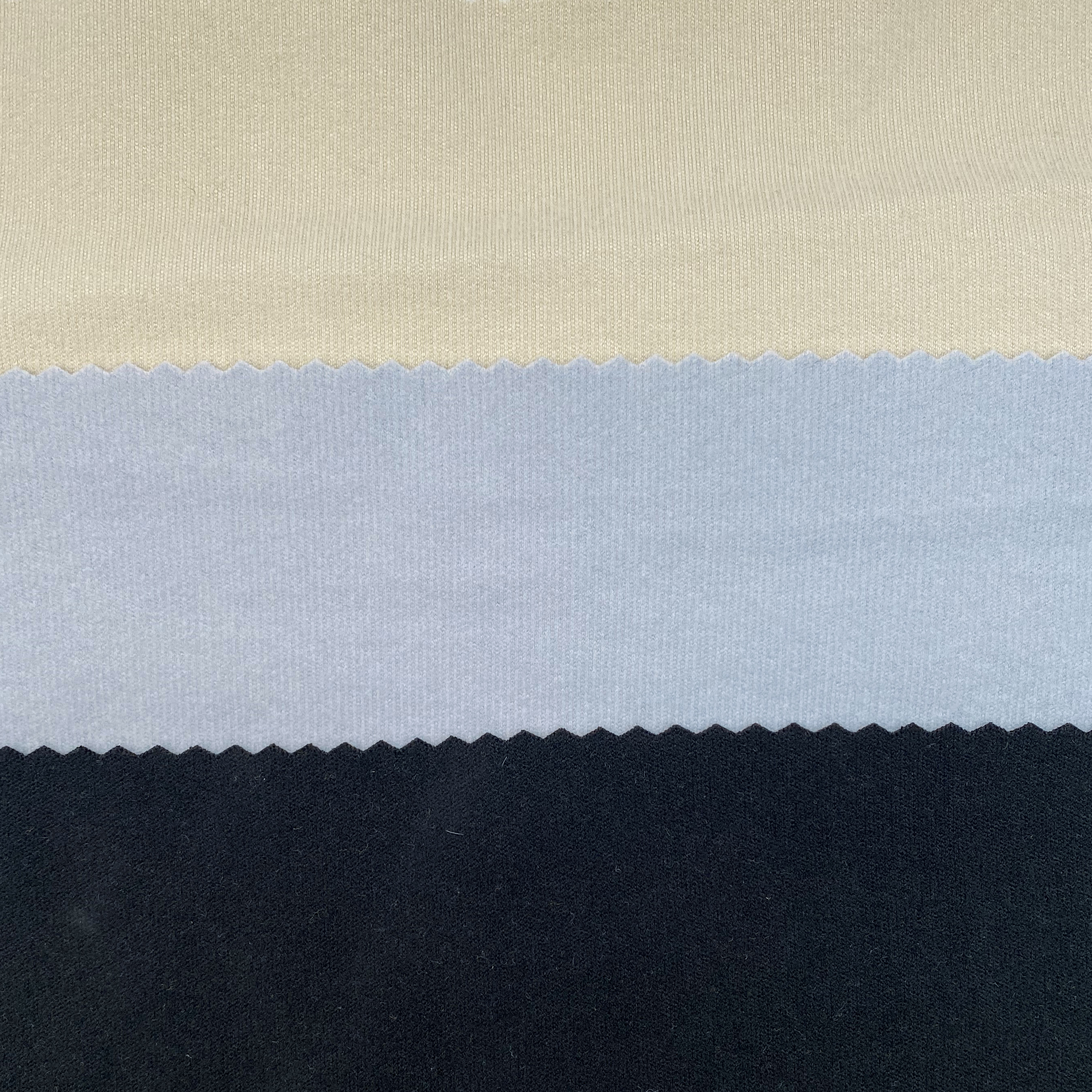

THERMAL UNDERWEAR FABRIC KF000279

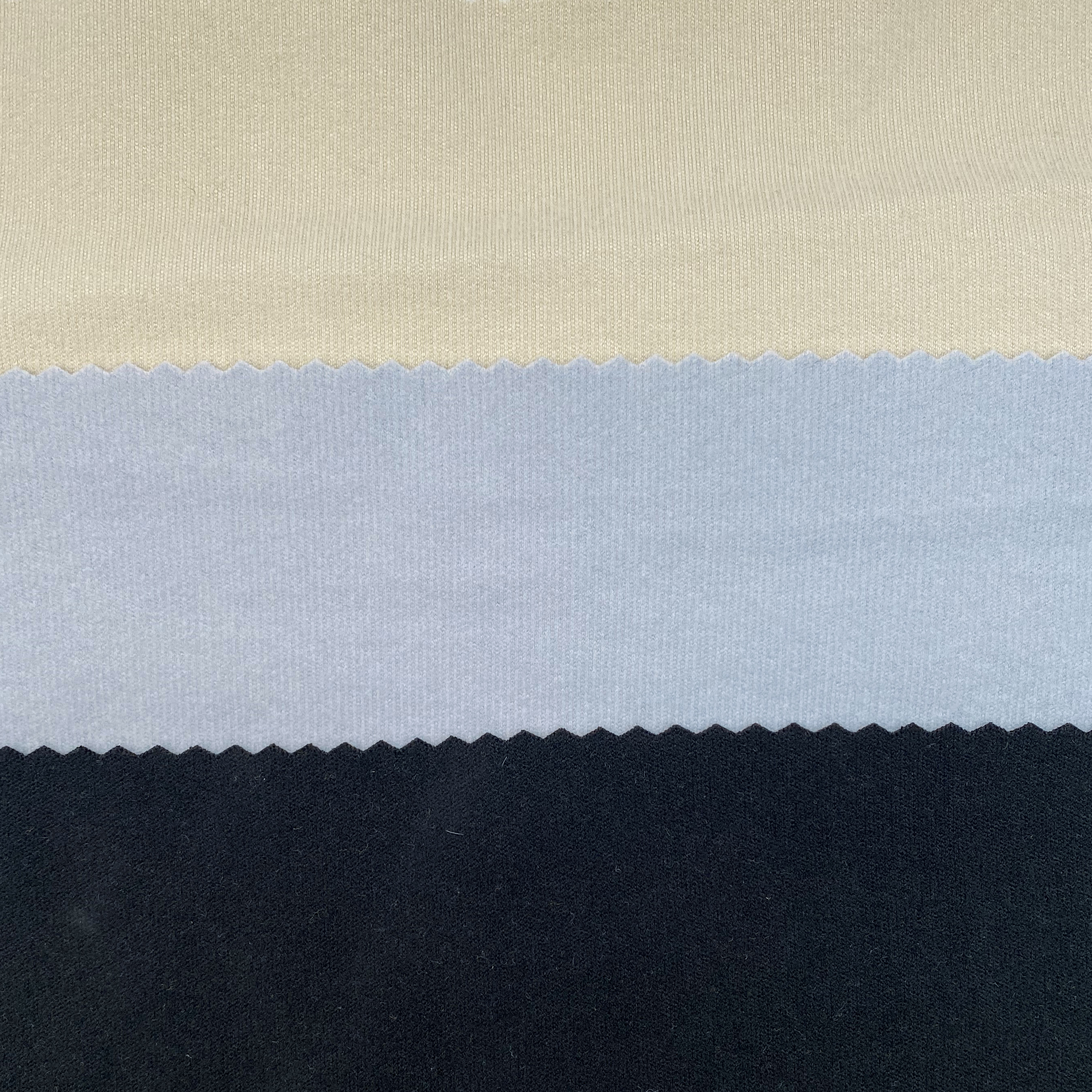

THERMAL UNDERWEAR FABRIC KF000279